Following extensive research into flight safety ICAO has developed standards for airfield light characteristics i.e. Beam intensity, orientation and colour as well as recommended practices in preventive maintenance that “shall be established at an aerodrome to maintain facilities in a condition which does not impair the safety, regularity or efficiency of air navigation.” Annex 14 Chapter 10.5 Visual Aids. As an airport operator there are two key questions that must be answered regarding airfield light fixtures:

Is your airfield lighting fit for purpose?

The aviation industry prides itself on there being no single point of failure in the system that could on its own, cause a fatal accident. Runway lighting is an important part of this system, especially in low visibility conditions.

1. Are your lights working safely i.e. serviceable according to ICAO and FAA?

There have been many recorded instances where an aircraft has been unable to visually locate a runway in low visibility conditions …Sometimes with disastrous consequences.

2. Are your lights in danger of becoming FOD (foreign object debris)?

There have also been many recorded occurrences of airfield lights becoming FOD.

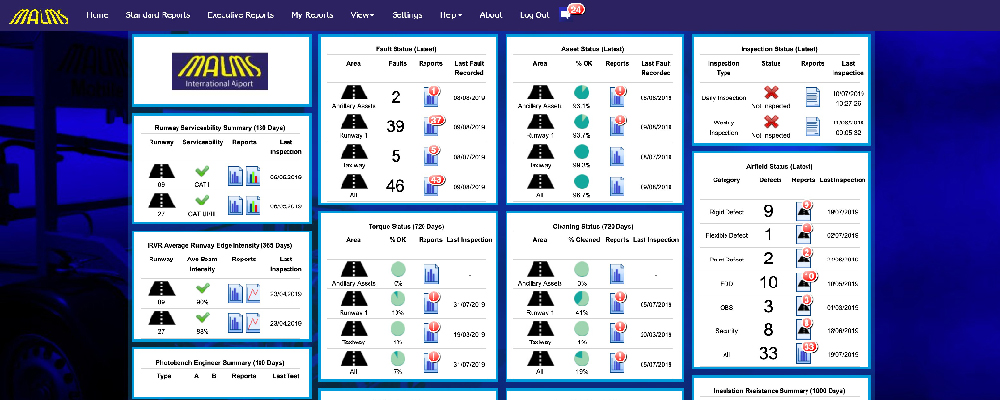

Why MALMS?

- Accuracy – MALMS products are designed and tested regularly to ensure accuracy.

- Independent – MALMS measurement systems are free from external influence and have a long established reputation for integrity.

- Easy to use.

- Rapid measurement – Allows the job to be done quickly and efficiently.

- MALMS products are robust, designed for the harsh airfield environment.

- Designed with fault tolerance to prevent operator errors with automatic monitoring and quality checks to ensure data integrity.

- Inbuilt diagnostics, dedicated support function plus global agency network provide effective customer support.

- Using MALMS will maximise runway availability, minimise costs and generate a rapid return on investment.

Investment in MALMS will:

- Reduce the risk of accidents to aeroplanes, passengers and staff.

- Reduce cost of diversions and delays.

- Ensure regulatory compliance.

- Optimise runway/taxiway availability as part of a Planned Preventative Maintenance System leading to improved passenger numbers.

- Support accurate IRVR calculation resulting in improved safety.

- Deliver effective light cleaning and navigation tools, reducing unplanned maintenance as part of an efficient preventative maintenance regime (Differential Maintenance), which is cheaper than alternatives such as block change.